10 Critical Checkpoints for Choosing the Right Cosmetics OEM/ODM Partner

- 2026-01-23 11:21:04

1. Certifications & Regulatory Compliance

Before anything else, verify that the manufacturer holds necessary certifications. These are non-negotiable for ensuring product safety and market access.

Key certifications to look for:

ISO 22716 (Cosmetics GMP)

ISO 9001 (Quality Management)

FDA Registration (for U.S. market access)

ECOCERT / COSMOS (for natural/organic products)

Local regulatory compliance (e.g., CPNP for EU, SFDA for China)

Ask for proof and check validity dates. A compliant factory minimizes regulatory risks for your brand.

2. R&D and Formulation Capabilities

A strong R&D team is the backbone of a good OEM/ODM partner. They should be able to translate your concept into a stable, effective, and safe formula.

Evaluate their:

In-house lab facilities and equipment

Expertise in different formulations (serums, creams, sunscreens, etc.)

Experience with specific ingredient types (vegan, organic, hypoallergenic)

Ability to customize or develop original formulas from scratch (ODM strength)

Request samples of previous work that match your product category.

3. Production Capacity and Equipment

Can the factory handle your order volume—from small batches to mass production?

Key questions to ask:

What is the minimum order quantity (MOQ) per product?

What is their daily/weekly production capacity?

Do they have dedicated production lines for different product types (e.g., liquids, powders, aerosols)?

Is equipment modern, well-maintained, and suitable for complex formulations (e.g., hot filling, cold processing, vacuum emulsification)?

4. Quality Control Systems

Consistent quality is what protects your brand reputation.

Inspect their QC process at multiple stages:

Incoming raw material inspection (with COA review)

In-process controls (pH, viscosity, microbiological testing during production)

Finished product testing (stability, compatibility, challenge testing)

Packaging quality checks (leakage, labeling accuracy)

Ask about their retention sample policy and how they handle batch failures.

5. Supply Chain and Sourcing Transparency

A reliable factory manages a transparent and ethical supply chain.

Important points to clarify:

Where do they source raw materials and packaging?

Can they provide traceability documentation for key ingredients?

Do they have backup suppliers to avoid delays?

Are they committed to responsible sourcing (e.g., RSPO, fair trade)?

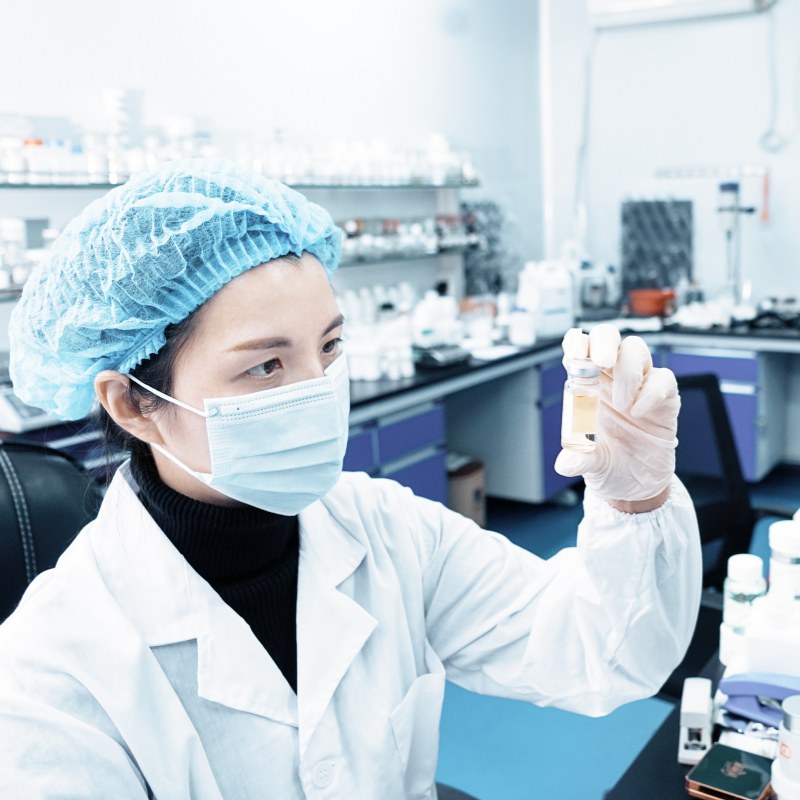

6. Hygiene and Facility Standards

The production environment directly impacts product safety.

If possible, request a virtual or on-site tour. Look for:

Cleanroom classifications (e.g., 100,000-class or better for sterile products)

Organized workflow to prevent cross-contamination

Proper sanitation protocols, air filtration, and staff hygiene practices

Separate zones for raw material storage, production, and finished goods

7. Packaging and Design Support

Packaging is part of the product experience.

Check if they offer:

In-house packaging design services (ODM)

Relationships with reliable packaging suppliers (bottles, caps, boxes)

Packaging validation (compatibility testing, drop tests)

Capabilities for custom packaging finishes (hot stamping, silkscreen, embossing)

8. Communication and Project Management

Smooth communication prevents misunderstandings and delays.

During initial contact, assess:

Responsiveness and clarity in communication

Dedicated account manager or project coordinator

Language capabilities (English-speaking staff for international brands)

Use of clear project timelines, sampling milestones, and regular update systems

9. Flexibility and Scalability

Your needs may evolve—your manufacturer should be able to grow with you.

Discuss:

Willingness to accommodate small initial orders with potential for scaling

Ability to handle last-minute changes or rush orders

Experience with international shipping and export documentation

Support for post-launch production adjustments

10. Reputation and Client Portfolio

Finally, look for social proof.

Ask for:

Case studies or portfolios of past/current clients

Testimonials or references (contact if possible)

Industry reputation—search for reviews or ask within your network

Be cautious if they are unwilling to share any client information (confidentiality agreements are normal, but generic examples should be possible).

Conclusion

Selecting a cosmetics OEM/ODM partner is a strategic investment. By thoroughly evaluating these 10 checkpoints—from compliance and R&D to communication and scalability—you can form a partnership that ensures product excellence, builds your brand’s credibility, and supports long-term growth.

Remember, the cheapest option is rarely the best when it comes to manufacturing. Choose a partner that demonstrates transparency, expertise, and a commitment to quality at every step.

Ready to evaluate your next manufacturing partner?

Contact us today to learn how our certified facilities, end-to-end services, and customer-focused approach can bring your cosmetic vision to life.